IWL Steel Fabrication Advantages

IWL Steel has a number of key advantages in our fabrication capabilities.

5-AXIS CNC Robotic Beam Line

Plasma cutting fabrication system downloads files directly from our 3D modeling software to process beam, channel, HSS and angle. Process functions include measure and cut to length, coping, hole drilling and piece marking.

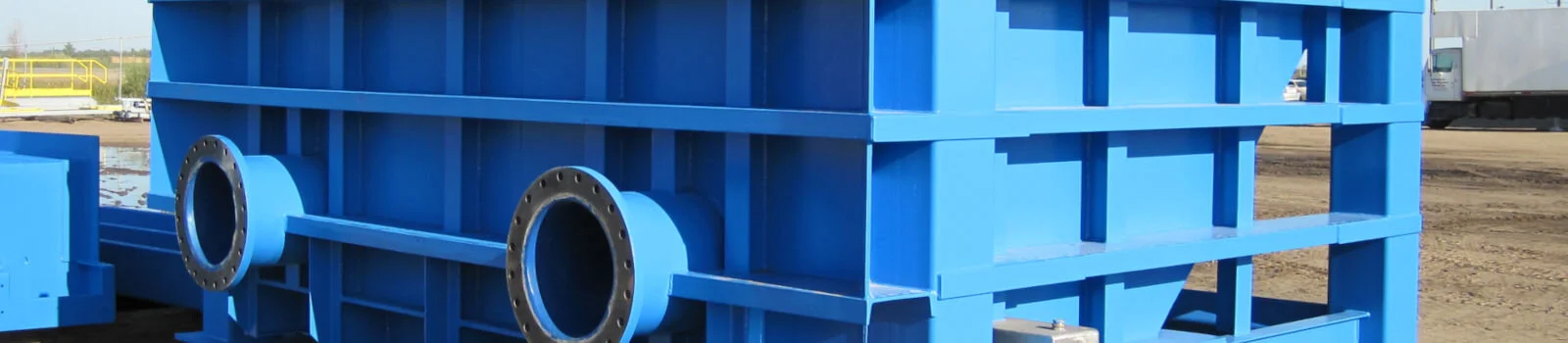

Machitech CNC with Pipe Fabrication Module

Direct file download for plate and pipe processing. Plate processing capabilities are up to a maximum size of 2” (thickness) x 8’-0 (width) x 24’-0 (length). Pipe processing capabilities are from 2” to 12” DIA at a maximum length of 20’-0.

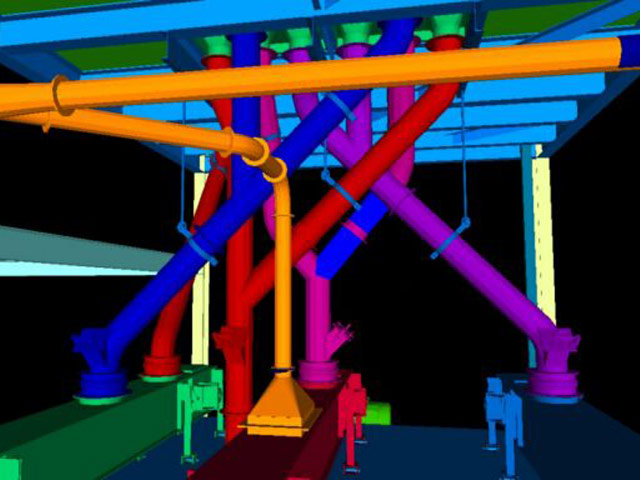

3D Modelling Software

Enables us to import our customer's information directly into our system. The centralizing of information allows for more integrated project management and timely deliveries. This model-based solution leads to increased productivity through direct interface with our automated fabrication equipment.

Tekla Structures

Allows for the streamlining of the manufacturing process. By modeling in 3D, we become more efficient while minimizing errors. Models from AutoCAD & Inventor can be imported into Tekla for fast quotation and drafting.

FTP Site with enhanced security and password protection; project information and shop drawings are uploaded to our secure site for customer viewing at their convenience.

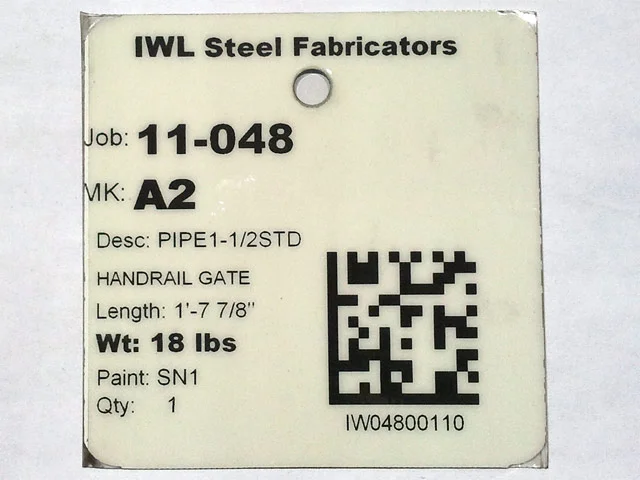

Bar Coding

IWL uses a computer-generated data matrix coding system for tracking material from the fabrication stage through to painting, loading and shipping to site. With bar code scanning, we are able to ensure accurate shipping documents and eliminate the possibility of an item not being loaded on the truck.